Automotive Rubber Parts

Your IATF 16949 Partner for Automotive Rubber

Custom Automotive Rubber Parts Manufacturer (OEM / Tier Suppliers)

Custom molded rubber components for sealing, vibration control, and protection in vehicle systems.

Fast DFM feedback, material selection support, and production-ready tooling.

Materials: EPDM, NBR, Silicone, FKM, CR, TPE/TPV

Processes: Compression / Injection / Transfer / Extrusion

Support: DFM review + tolerance control + sampling → mass production

Automotive Applications We Specialize In

- Custom engine mounts and isolators

- Fuel system seals and gaskets

- Turbo boots and intake hoses

- Shock absorber bushings

- Anti-vibration mounts

- Custom control arm bushings

- Door seals and weather stripping

- Noise dampening components

- Custom grommets for wiring harnesses

- Climate control gaskets

- Air duct seals and connectors

Common Automotive Rubber Challenges We Solve

Temperature Extremes: Engine bay components face -40°F to 300°F+ swings. We utilize high-grade EPDM and Silicone to ensure stability.

Chemical Exposure: Fuel, oil, coolant, and cleaning agents attack standard rubber. Our fluorocarbon and nitrile compounds offer superior resistance.

Vibration & Fatigue: Automotive parts endure millions of vibration cycles. Our custom-engineered geometry maximizes part longevity.

Tight Tolerances: Modern vehicles require sub-millimeter precision. Our IATF-certified processes ensure every part fits perfectly every time.

Why IATF 16949 Certification Matters for Your Automotive Project

Our IATF 16949 certification isn't just a badge—it means higher reliability for your supply chain:

- PPAP Support: Full production part approval process documentation for seamless OEM integration.

- Process Control: Real-time SPC monitoring on all critical dimensions to eliminate defects.

- Traceability: Full lot tracking from raw material batch to the finished component in your hands.

- Continuous Improvement: Documented corrective action on any non-conformance to ensure evolving quality.

Engineered rubber components for automotive excellence

We design and mold parts that solve sealing, damping, protection, and durability challenges in cars and trucks.

Rubber Grommets

Cable/wiring grommets, firewall grommets, panel grommets

Learn more

Bumpers, Pads, and Isolation Mounts

Engine mounts, bushings, vibration isolators, bumpers/dampeners

Learn more

Extruded Rubber Profiles and Tubing

Extruded rubber profiles for doors, windows, and body sealing.

Learn more

Seals, Gaskets, and O-Rings

O-rings, oil seals, window/door seals, weatherstripping

Learn more

Rubber Bellows and Boots

CV joint boots, steering boots, suspension system boots

Learn more

Verified quality through testing and compliance

Our commitment to excellence is backed by detailed compliance reports and product testing documentation. You’ll have full confidence in the durability and performance of every component we produce.

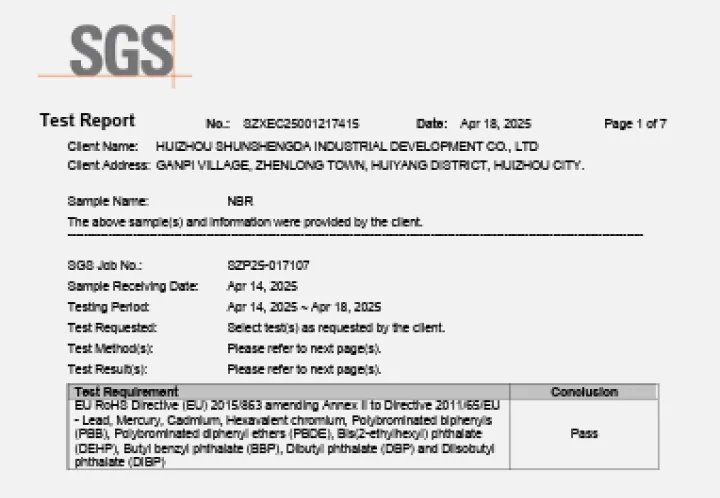

NBR RoHS Compliance Report

Our products meet European Union requirements as per their Restriction of Hazardous Substances directive.

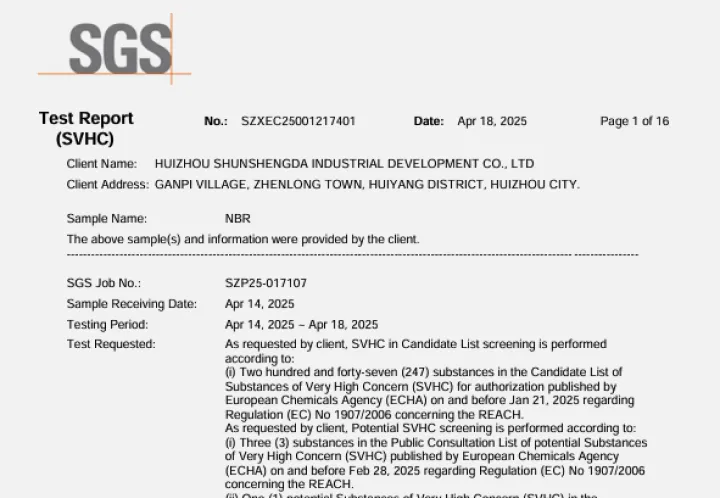

NBR REACH Compliance Report

Our products meet European Union requirements as per their Registration, Evaluation, Authorization and Restriction of Chemicals directive.

Voices from the automotive industry

Read how our customized automotive rubber molding products drive performance and peace of mind.

Elevate vehicle looks and performance with top-shelf custom rubber parts

When every seal, bumper, or boot must perform flawlessly, Fenlora delivers automotive rubber products that stand up to the test.